Empowering Air Compressors with IoT: A New Era in Remote Monitoring

Introduction

In today’s industrial landscape, efficiency and reliability are paramount. One vital component that drives various manufacturing processes is the air compressor. Traditionally, monitoring air compressors involved manual checks, which can be time-consuming and prone to human error. However, the advent of the Internet of Things (IoT) technology has revolutionized the way air compressors are managed and monitored. This article explores how IoT empowers air compressors through remote monitoring, enhancing operational efficiency and reducing downtime.

Understanding IoT and Its Importance

The Internet of Things consists of interconnected devices that communicate and exchange data over the internet. In industrial settings, IoT allows for real-time monitoring and management of machinery, including air compressors. By embedding sensors and smart devices within air compressors, operators can access crucial data remotely, facilitating quick decision-making and proactive maintenance.

Benefits of Remote Monitoring for Air Compressors

1. Real-Time Data Access

With IoT-enabled air compressors, operators can access real-time data on performance metrics such as pressure, temperature, and energy consumption from anywhere in the world. This capability allows for immediate adjustments, optimizing performance and prolonging the lifespan of the equipment.

2. Predictive Maintenance

One of the most significant advantages of IoT is the ability to predict equipment failures before they occur. By analyzing historical data and detecting anomalies in performance, IoT systems can send alerts for maintenance needs, preventing unexpected breakdowns and reducing costly downtime. This predictive approach ensures that maintenance is performed only when necessary, saving both time and costs.

3. Enhanced Efficiency

IoT solutions can optimize the operational parameters of air compressors by adjusting settings based on real-time data. For instance, if demand fluctuates, the system can automatically regulate the compressor’s output, ensuring that energy is used efficiently and minimizing wastage. This not only reduces operational costs but also supports sustainability goals.

4. Improved Safety

Remote monitoring enhances workplace safety by allowing operators to keep an eye on compressor performance without being physically present. Parameters outside normal ranges can trigger automatic alerts, prompting timely interventions. This capability reduces the risk of accidents and protects workers from potential hazards.

5. Data Analytics and Reporting

IoT devices collect vast amounts of data, which can be analyzed to identify trends and performance patterns. Business leaders can generate comprehensive reports that inform strategic decisions regarding equipment usage and investments. By leveraging data analytics, companies can optimize their operations and enhance their competitive edge.

Implementation of IoT in Air Compressors

To integrate IoT into air compressors, companies typically follow these steps:

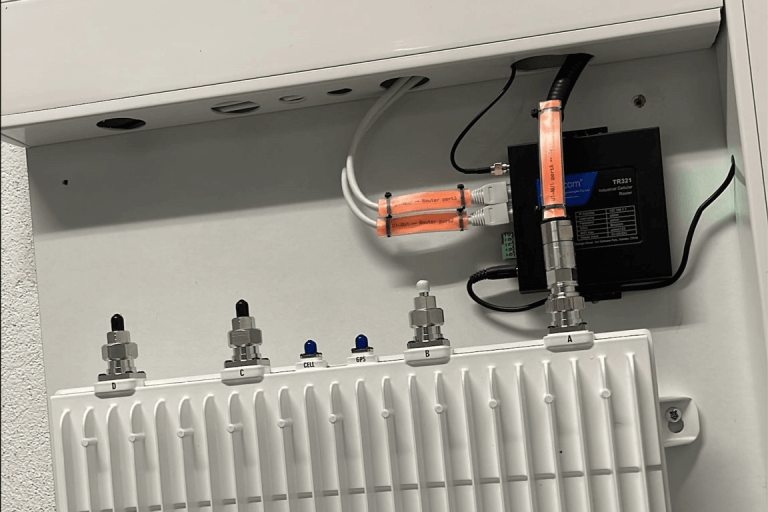

Sensor Installation: Equip air compressors with sensors that monitor key metrics such as pressure, temperature, and vibrations.

Connectivity: Utilize wireless protocols (like 4G, Wi-Fi or LoRa) to ensure seamless communication between devices and cloud platforms.

Data Management: Implement a cloud-based management system that collects and processes data from all connected compressors.

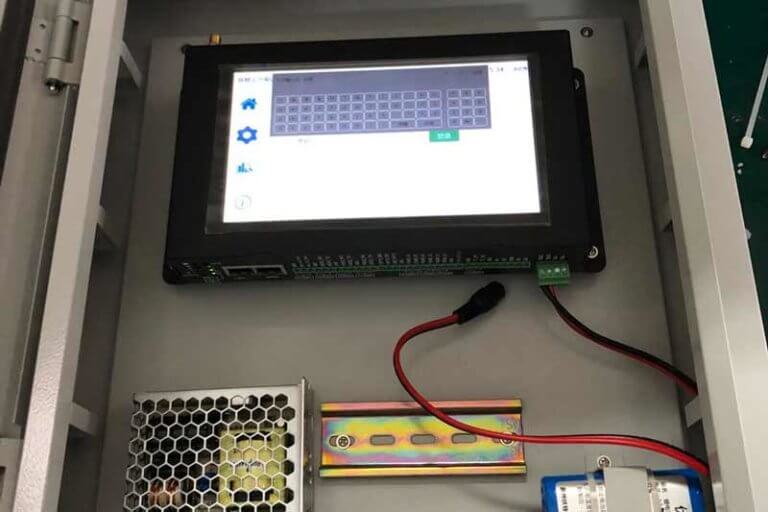

User Interface: Develop an intuitive dashboard that allows operators to visualize data, receive alerts, and manage compressors remotely.

Continuous Improvement: Regularly update software and algorithms to enhance functionality and maintain security.

Challenges and Considerations

While the benefits of IoT-enabled remote monitoring are significant, there are challenges to address:

Data Security: Protecting sensitive data from cyber threats is crucial. Implementing robust security protocols is essential.

Integration: Ensuring that new IoT systems integrate smoothly with existing infrastructure can be complex and may require expert consultation.

Cost: Initial investments in IoT technology can be substantial; however, the long-term savings and efficiency gains often outweigh these costs.

Conclusion

The integration of IoT technology into air compressor systems marks a transformative shift in how industries approach equipment management. With real-time monitoring capabilities, predictive maintenance, and enhanced operational efficiency, IoT empowers businesses to improve reliability, reduce downtime, and ultimately drive profitability. Embracing this technological advancement represents a significant step forward toward a smarter, more connected industrial future.

Comment