Revolutionize Air Compressor Monitoring with Bivocom IoT Router TR321

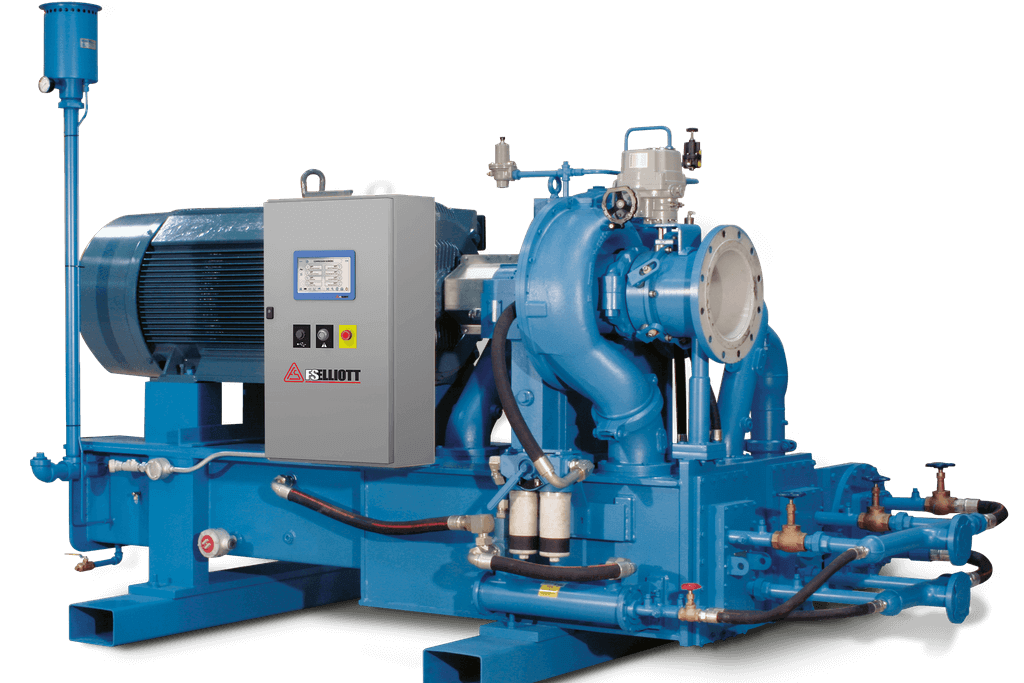

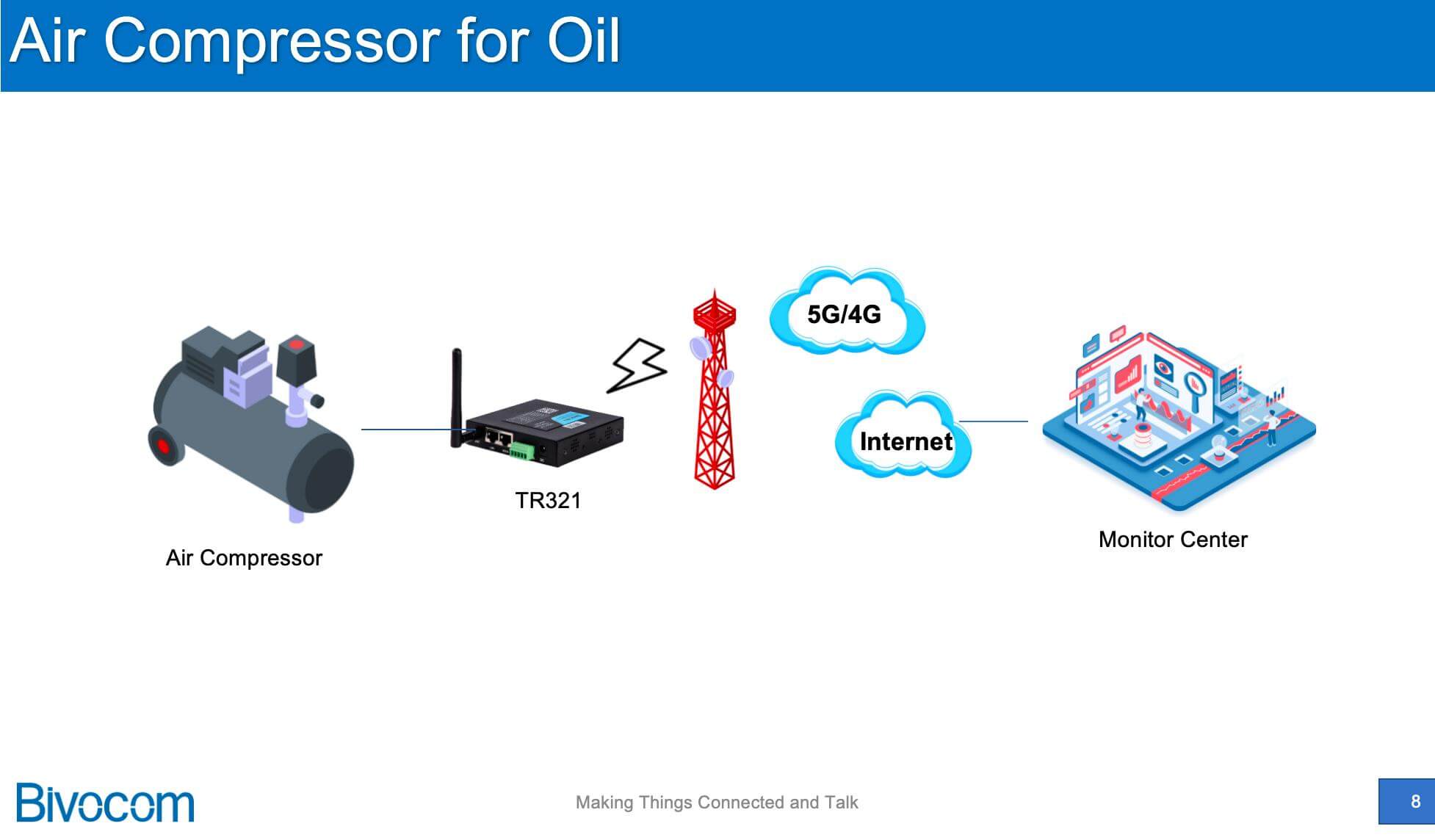

In an era driven by data and connectivity, the need for efficient monitoring and management of industrial equipment is more critical than ever. Air compressors, integral to many manufacturing processes, require continuous oversight to ensure optimal performance and prevent unwarranted downtime. Bivocom, a leading provider of industrial IoT solutions, introduces the TR321 IoT router as a game-changer in monitoring air compressor status through advanced capabilities such as current and voltage monitoring, temperature sensing, pressure tracking, and predictive maintenance alerts.

Comprehensive Monitoring of Air Compressor Operations

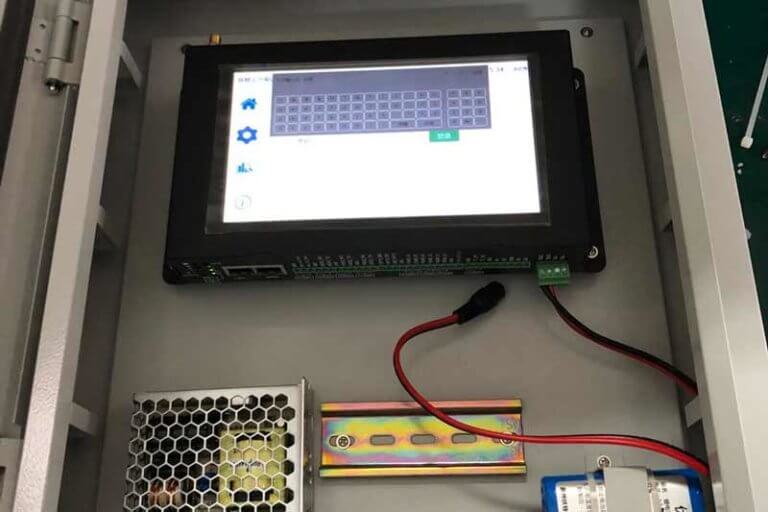

The Bivocom IoT router TR321 provides a comprehensive solution for monitoring various parameters essential for air compressor health and performance:

Current, Voltage, and Power Monitoring: By interfacing with the motor, the TR321 captures real-time data on current, voltage, and power consumption, enabling operators to track energy usage and detect irregularities that may indicate motor issues.

Temperature Sensing: The TR321 monitors the temperature of the heatsink and oil, alerting users to potential overheating conditions that could jeopardize compressor efficiency and longevity.

Motor Speed Tracking: By measuring the speed of the motor, operators can assess how efficiently the compressor is running and detect any deviations from optimum performance levels.

Pressure Monitoring: The TR321 keeps tabs on pressures at critical points in the system, including the screw compressor and the tank, allowing for the timely detection of pressure fluctuations that may signify leaks or inefficiencies.

Airflow Rate Measurement: Monitoring the airflow rate helps operators gauge the compressor’s output capacity, identify blockages, and optimize performance for enhanced productivity.

Operational Hours Tracking: The TR321 logs both running and loaded hours, providing insights into equipment usage patterns and facilitating maintenance scheduling based on actual operational data.

Predictive Maintenance Alerts: Leveraging the data collected, the TR321 calculates the time remaining before scheduled maintenance is due, enabling proactive maintenance planning to prevent costly breakdowns.

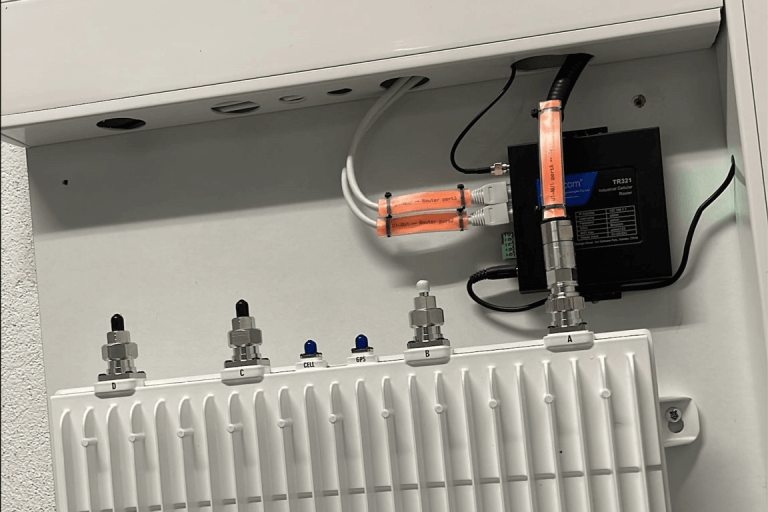

Enhanced Connectivity and Compatibility

The Bivocom IoT router TR321 boasts versatile connectivity options and protocols, including:

RS485 and Ethernet Ports: Allows for seamless integration with various devices and protocols, enhancing interoperability within the existing infrastructure.

MQTT Support: Facilitates secure and efficient data transmission, enabling real-time monitoring and analysis of compressor parameters remotely.

Modbus RTU/TCP Compatibility: Enables easy integration with Modbus-compatible devices, simplifying communication and data exchange in industrial environments.

Unlocking the Potential of IoT for Air Compressor Management

By harnessing the power of the Bivocom IoT router TR321, industrial facilities can revolutionize their air compressor monitoring practices, leading to increased efficiency, reduced downtime, and cost savings. Real-time insights into critical parameters combined with predictive maintenance alerts empower operators to take proactive measures, optimize performance, and extend the lifespan of air compressor systems.

Investing in IoT solutions like the Bivocom TR321 not only ensures a smoother operational experience but also positions businesses at the forefront of Industry 4.0 innovation. Embrace the future of industrial monitoring with Bivocom and elevate your air compressor management to new heights of efficiency and reliability.

Comment