What Is Air Compressor?

Wikipedia gives air compressor definition as below.

An air compressor is a pneumatic device that converts power (using an electric motor, diesel or gasoline engine, etc.) into potential energy stored in pressurized air (i.e., compressed air). By one of several methods, an air compressor forces more and more air into a storage tank, increasing the pressure. When the tank’s pressure reaches its engineered upper limit, the air compressor shuts off. The compressed air, then, is held in the tank until called into use. The energy contained in the compressed air can be used for a variety of applications, utilizing the kinetic energy of the air as it is released and the tank depressurizes. When tank pressure reaches its lower limit, the air compressor turns on again and re-pressurizes the tank. An air Compressor must be differentiated from a pump because it works for any gas/air, while pumps work on a liquid.

There are two main designs for the majority of air compressors: reciprocating piston air compressors and rotary screw air compressors.

Who Uses Air Compressors?

Air compressors have been widely used in many industries and applications, and different application calls for different type of air compressors. Air compressors can be grouped into three classifications: consumer grade, professional grade and industrial grade

- Consumer Grade

Small and portable air compressors that we’re using in our daily life, such as, air compressor pumps to inflate vehicle and bicycle tyres, or pressure washing, spray painting, etc.

- Professional Grade

Construction may use the air compressor to power the drills, hammers and compactors, while for agriculture or farming, the air compressors have been used to power tractors, sprayers, pumps, and crop conveyors.

- Industrial grade

For manufacturing, air compressors are used to power the conveyor belts, sprayers, presses, and packaging. Besides, application like Heating, Ventilation and Air Conditioning (HVAC), Rotary screw air compressors conduct vapour compression refrigeration that entails compressing air vapours, raising the temperature, and modulating the all-important refrigerant cycles. Oil drilling relies on air compressors for functionality in the energy sector.

Air Compressor Remote Monitor System In Crude Oil Production

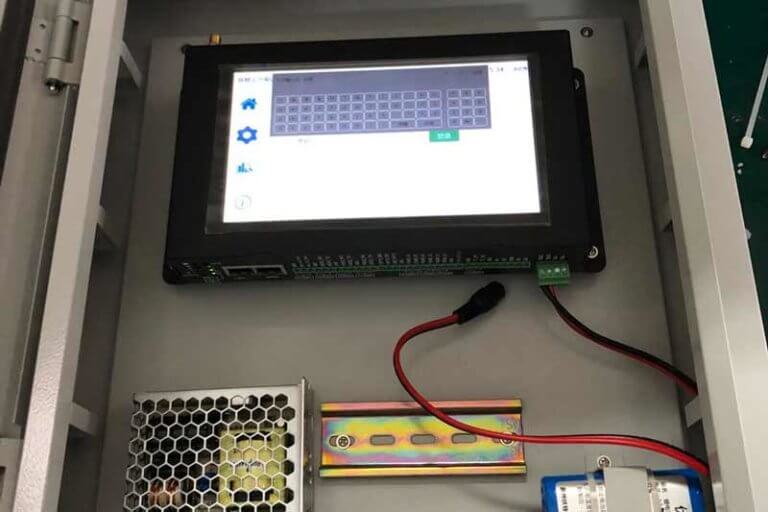

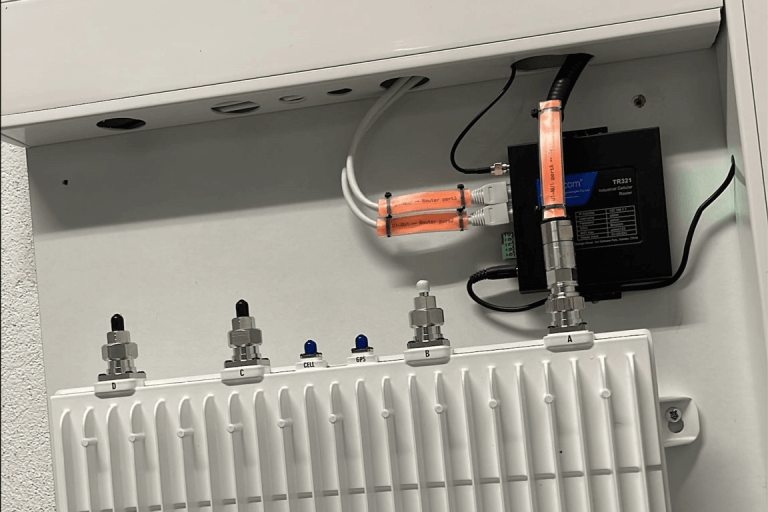

Today, we’re going to share with you a case study using Bivocom industrial 4g cellular IoT router TR321 for remote monitoring and managing air compressors that are used in crude oil production in USA. The air compressor is used to pull the natural gas from oil storage tank and put it in gas pipeline, so instead of burning it all, the oil company can compress and put it in the natural gas pipeline, and together with a VRU(Vapor Recovery Unit) system, it helps to prevent emissions vented to the atmosphere, and save money for oil companies.

Bivocom TR321 is a compact designed industrial grade 4g cellular IoT router, with interfaces of RS232, RS485 and RJ45 for diverse type of controllers, sensors, and it supports industrial protocols, like Modbus RTU/TCP, and able to convert Modbus data to JSON and transfer it over MQTT via 4G/3G/2G. It has been widely used in industry 4.0, digital signage, IP camera, vending machines, ATM, EV charging points, solar power, etc.

Related links:

What is CNC Machining? Understand This Fascinating Manufacturing Process

3 Comments